Vacuum cooling

Many years of research and development led to a spectacular result, the vacuum cooling system. Grass needs a temperature of at least approximately 6 degrees to grow. By reducing the temperature below this level, the growing process of the grass plant will slow down and, subsequently, less heat will be produced. Using traditional cooling, you would need several days to cool a pallet with turf rolls down to the required temperature. That would be economically ineffective, not to mention the environmental consequences of this process.

The solution is as simple as it is effective: cooling under extreme low pressure, in other words vacuum cooling. This technique allows cooling a full lorry load within 20 minutes. Delivery of the turf no longer requires using so-called refrigerated vans in warm weather conditions. This technique enables turf to be kept in stock as well as delivery to distant destinations in Europe, while retaining the quality.

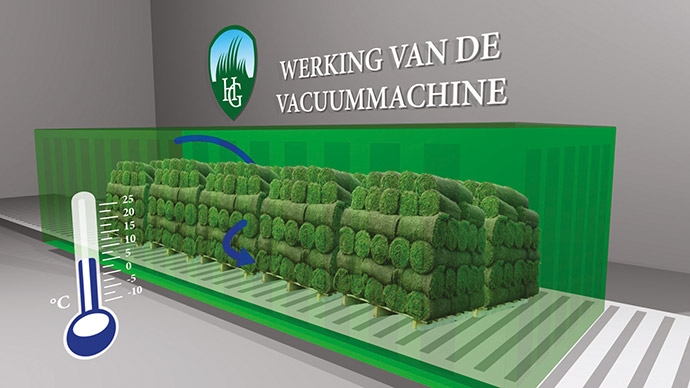

Step 1

Vacuum – cooling is a new technique in turf cultivation. It enables increasing the shelf life of the grass considerably and consequently guaranteeing the quality of the grass. To prevent the grass from heating up, the grass rolls are vacuum cooled down to 3-4°C.

Vacuum – cooling is a new technique in turf cultivation. It enables increasing the shelf life of the grass considerably and consequently guaranteeing the quality of the grass. To prevent the grass from heating up, the grass rolls are vacuum cooled down to 3-4°C.

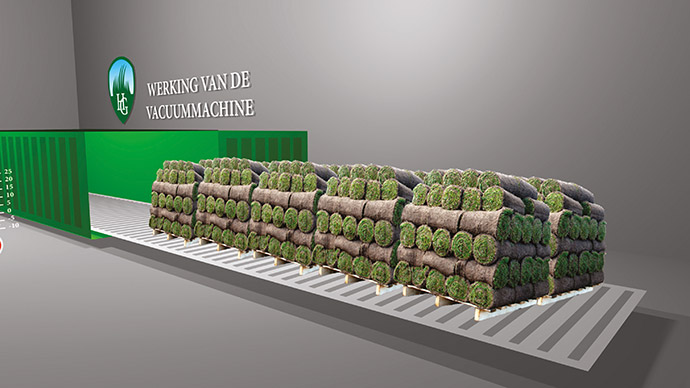

Step 2

The turf is transported through the cooling system on a belt, whereupon the pressure is reduced allowing the moisture in the turf to evaporate. The evaporation process extracts the energy (heat) from the product. As a result, the products can be cooled right down to the core to 3 or 4 °C within a period of 20 to 30 minutes.

The turf is transported through the cooling system on a belt, whereupon the pressure is reduced allowing the moisture in the turf to evaporate. The evaporation process extracts the energy (heat) from the product. As a result, the products can be cooled right down to the core to 3 or 4 °C within a period of 20 to 30 minutes.

Step 3

The fast and uniform cooling results in a considerably longer shelf life of the grass while its quality is retained and you will have about 2 more days to distribute and/or process the turf!

The fast and uniform cooling results in a considerably longer shelf life of the grass while its quality is retained and you will have about 2 more days to distribute and/or process the turf!

Step 4

After the cooling process the turf is ready for fine distribution. While waiting for the carriers, the turf is temporarily stored in cold rooms.

After the cooling process the turf is ready for fine distribution. While waiting for the carriers, the turf is temporarily stored in cold rooms.

English

English Nederlands

Nederlands Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Polski

Polski Русский

Русский